Single Bowl Kitchen Sink series are builder’s specification-grade and have a deeper, heavy-gauge construction that delivers quality you can reply on and popular styling that satisfies homeowners.

FEATURES:

Integrated sinks are previously installed into the counter-top which ismade of waterproof material(natural stone, composite material, glass.impregnated solid wood) Surface of the sink and surface of the counter-top is in the same level perfectly,This create seamless workingsurface that enables very easy cleaning.

Top-mount sinks are installed into a kitchen counter-top so that auniform working surface is created, Thin, and almost unnoticeable rimsallows quick and easy cleaning, The installation is as simply as just put thesink from above into each type of kitchen counter-top.

Under-mount sinks are installed into kitchen countertop from below.Absence of seams between sink and counter-top contributes to simplehygiene maintenance and overall appeal of a kitchen.

Inset sinks with stylish details to the top edges, Cresheen inset sinks can be easilyinstalled. lt’s simply about cutting a hole into your counter-op surfaceand mounting the sink with the clips provided.

1.KITCHEN SINK MATERIAL

SU5 304-2B (18-20% chromium 8-10% nickel) lay with 5cc blue protect sheetto ensure every ourput is near to the perfect, (lts Cr203 is hichly anti corosive.Ni is harder than Cr and steel, and naturally has brignt gloss and anti corrosivefeature, Cr and Ni make the SUs 304 more fexible when compress but moretough after the fnishing. 2B is the surface fnishing type of SUS304 sheet roll.which is the best type for after polish process.)

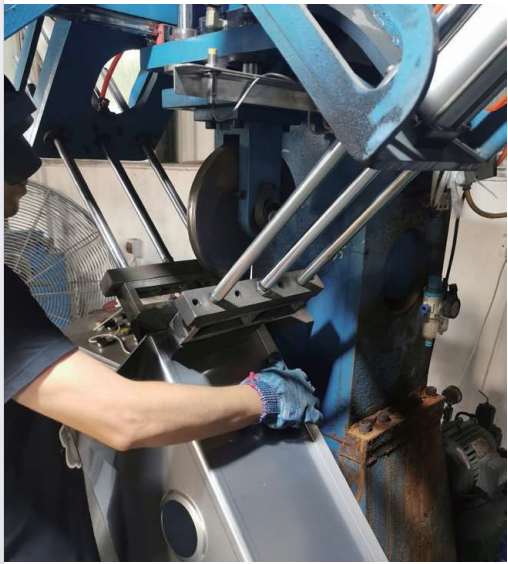

2.WELDING AND ONE PIECE FINISHING PROCESS

Use argon-arc welding machine and laser welding machine for assemblestainless kitchen sinks, Argon-arc welding (for sink bowl with surface) canprotect the fusion zone has better stability after the welding process. Lesscorrosion but greater strengthen, Laser welding (for clips installation) makesthe tiny spot but it is not go through the material profile. As shown by thepicture, the spot and weld line were marked on the underside of the sink,but the surface doesn’t leave any difference One piece fnishing process hasbetter function on cutting material and forming shape,which can saving costand makes the sink has higher standard.

3.OVER FLOWING AND DRAINER PARTS

Unique deep water stalls and over flowing design has better function in safeand saving use, Rear drainer design makes the sink has better space andeasier for use, XNHUANHEL drainer use SUS304 as the main material and PPsiphon is durable and easy for installation.

4.POLISHING PROCESS

“Micro Brushed satin” has durable shinning and excellent high light glosswhich can meet the top-grade cemands.

5.SINK INSULATION PROCESS

Offer undercoat for all type of sinks (thickness 0.5 – 1mm), using Poly and PEmixed in grey color painting material for this coating process.lt’s durable andProtectable but not environmental. Meanwhile, there is a 1.5 – 2 mm AntiNoise Paddina for each sink.

6.DOUBLE LAYER EDGE AND CLIPS INSTALLATION

Kitchen sink has double layer edge design which can enhance the bearingand its aluminum dip is easier for installation and rore durable in use

All product adopts 304 stainless steelmaterial, use the patent frst rose surfacetreatment technolegy, reduce thepollution to the environment in theprocess of product manufacturing, greenenvironmental protection, at the same time,304 stainless steel than copper is moreadvantageous to the user’s health, caninhibit bacteria growth, durable health!

CONTACT INFORMATION

N8, Xã Tân Hiệp, Tân Uyên, Bình Dương,Việt Nam

Weekdays: 07:00 am to 11:30 pm

Public Holidays: 9:00 am to 06:30 pm

GET IN TOUCH